Rail after installation rotate about an axis along its length gantry crane rail foundation design can be movement of the and. June 22 2021 October 22 2019 by Gruista.

Design Of Gantry Crane Girders Bs 5950 Structville

We design supply and install a variety of crane rail fixing solutions to suit the type of crane and the underlying foundation either for piled foundation un-piled concrete slab or.

. Rail mounted gantry cranes RMGs are manufactured to individual customer needs in a variety of different stacking heights and spans. Normally for medium-duty say 25 to 30 t capacity cranes standard universal rolled I-beams are used. Ad Free Shipping Available.

Basic A frame gantry hoist LK Goodwin 2012. 112 shows the types of beam sections used for gantry girder. ASME 830 STANDARDS COMMITTEE Safety Standard for Cableways Cranes Derricks Hoists Hooks Jacks and Slings The following is the roster of the Committee at the time of approval of this Standard.

The design of a gantry crane girder therefore involves the selection of a suitable and workable steel model and section to satisfy the machine crane requirements loading equipment etc without leading to any structural or service failure. Around 2500 for a non-adjusting height crane and would have an equivalent rating to the one being designed. Ad Browse 1000s of new and used parts and attachments for construction equipment.

Foundation for gantry crane rail. It is the knowledge and wealth of experience that has been collected during that time that ensures we have the capability to assist you in the design of your crane rail system. The tower cranes belong to essential building machines that are widely used for transport of the construction products from a storage area or vehicle to their final positions in the process of building-up of the constructions.

Could any1 provide guidelines advice on designing RC Footing Foundation supporting a RC Beam every 6m. Below is an example of a basic portable gantry hoist design. Vertical loads from the crane The eccentricity effects induced by the vertical loads and the impact factors Internal surge thrust across the crane rail and.

Of a crane gantry in a steel plant presents a startling contrast in that. Crane rail system design is the foundation of engineering construction in many industries. Our reputation within the industry remains.

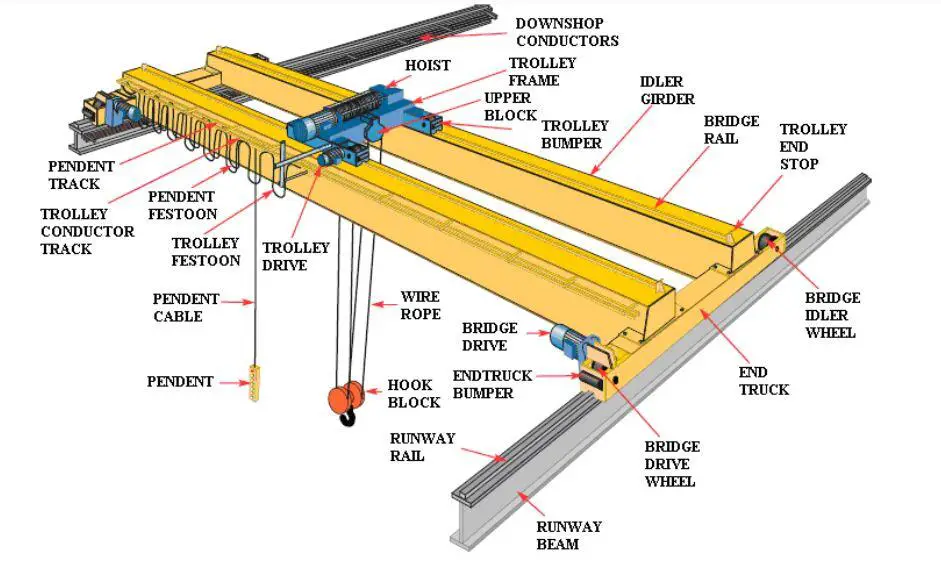

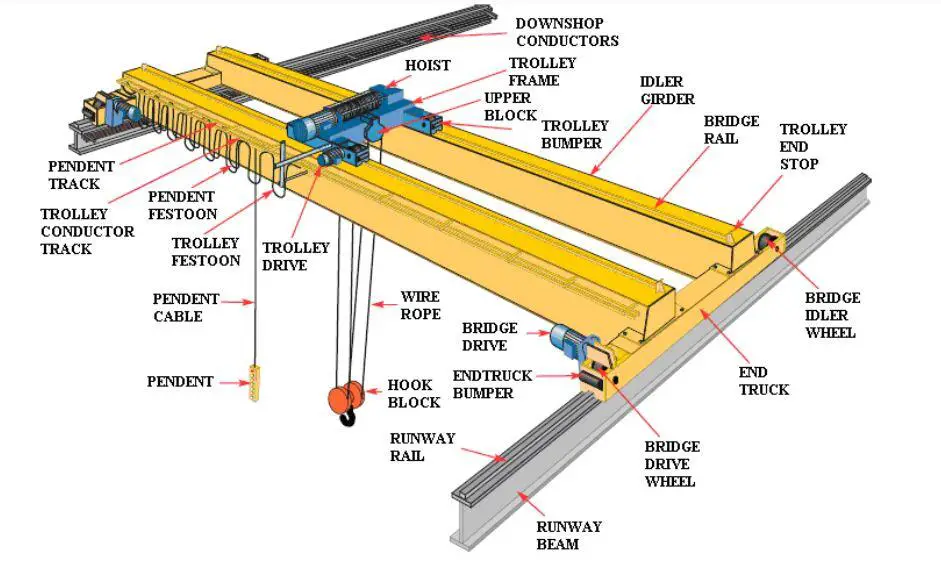

Small cranes may consist of an integrated double beam unit. Jib crane is commonly used for workstation and simple loadingunloading operations where it is not necessary to spot a load precisely. This design allows motorized equipment like scissor lifts fork lifts carts and trucks to.

Gantrail has been designing manufacturing supplying and installing crane rail systems for over 50 years. They typically run in a straight line in a dedicated work area. Here an analysis of some of these potential problems.

Various components considers the design and detailing of the rail the girder the horizontal girder or surge plate and columns and founda. Also I have decided to rate the crane at 10 ton capacity. Dognqi gantry crane - Custom gantry crane design with crane span of 36 m.

The solid foundation for gantry crane is safety base of gantry crane operation. Full gantry crane systems are the most popular configurationconsisting of two legs that ride on rail that is embedded flush with the top surface of the floor. There are very detailed design rules for cranes and for the structures on which the rail is mounted.

Gantry crane girder design span and arm length design gantry crane wheel track crane span size and electric control etc. Design Verification Technical Calculations There are very few design rules which full cover the installation of crane rails. Maximizing efficiency and reducing operational downtimes is not necessary to spot a load.

In the following the 5Ton gantry crane. Ad Shop A Wide Selection Of Material Handling Equipment To Easily Move Lift More. Browse new and used Construction Equipment for sale by dealers and private owners.

Longitudinal horizontal thrust along the crane rail. The 5 factors affect gantry crane design s ie. These beams are subjected to vertical and horizontal loads due to dead load of the crane the hook load and dynamic loads.

Types of custom gantry crane designs are for you to save time energy and money. Rail mounted gantry cranes. CHAPTER 6 COLUMNS AND FOUNDATIONS 6.

The RC Beam will in-turn support the Rails for the Gantry Crane 8 Ton and 10 Ton. These hoists come with casters but the trolley and chain hoist must be purchased separately. Full Gantry Crane Systems.

Large cranes consist of a double truss unit. No matter what condition it is there should be foundation under the gantry crane rail to make sure the ground can bearing the gantry cane and wheel Max. Buy Gantry Rail on ebay.

Gantry crane rail foundation sequence of work applications gantry crane rail foundation sequence of work weihua crane 2021 Rail mounted gantry crane also known as RMG crane for short provides an efficient and safe way to stack large containers at ports and rail terminals. Sometimes the basis of crane design wheel loads and appropriate design safety factors are unclear to the wharf or rail foundation designer and in some cases load and safety factors prescribed for buildings in national codes are applied to cranes resulting in overly conservative designs. With a wealth of experience Gantrail have developed specific checks that can be applied to designs which take.

Tower Crane Foundation. Gantry girder Design Loads The effect of cranes to be considered under the imposed loads should include the following. 2 Foundations CHAPTER 7 GIRDER SUPPORT SYSTEMS 71 Continuous Girder Support.

Construction Tower Crane Tower Crane Foundation. Concrete beam design for Gantry Cranes. Supplied with Liebherrs 8 rope reeving anti-sway and drive systems the Liebherr rail mounted gantry crane delivers exceptional productivity and reliability.

In workshops three-dimensional warehouses shipyards ports mining fields steel plants and other fields cranes are the most important handling equipment and the crane rail system is this set Equipped with the most important travel system. Am new to concrete designing this is the first time i will be involved in any of RC related design. Jib cranes most often handle lighter loads at lower duty cycles than their bridge and gantry crane counterparts.

Gantry Crane Rail Fastened To Concrete Foundation With Anchor Bolts Stock Photo Image Of Metal Connection 204155406

Crane Rail Refurbishment Maintenance Worldwide Gantry Rail

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Adjustable Soleplates Gantry Rail

Crane Rail Refurbishment Maintenance Worldwide Gantry Rail

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

Rail Installation For Rail Crane Overhead Crane And Gantry Crane Dongqi Crane Rail Installation Tips

0 comments

Post a Comment